Blood Collection Tube Production Line

| Project Name | Blood Collection Tube Production Line | Mold Cavities | 1-96 cavities |

| Mold Steel | S136 | Syringe Size | According to the customers |

| Injection Gate | Hot Runner | Syringe Material | PP, PET |

| Packing | Wooden Box | Delivery Time | 45-65 working days |

| Servo Energy Saving Machine | 110T-4000T | ||

| We provide the complete syringe solution. | |||

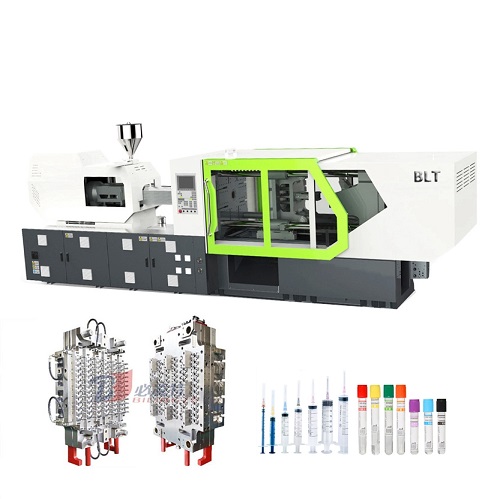

Blood Collection Tube Production Line---Injection Molding Machine

We use high-performance servo dynamic control system,as the power source the oil pump,have the characteristics high speed We use high-performance servo dynamic control system,as the power source the oil pump,have the characteristics high speed response, energy saving.low noise .high-control precision,and a breakthrough in the perfect connection of the electrical servo and hydraulic drive system. breakthrough in the perfect connection of the electrical servo and hydraulic drive system.

Suitable for medical disposable syringe, blood collection tube, medical test tube and measuring cup etc.We can offer customized machine according to customers special requirements.

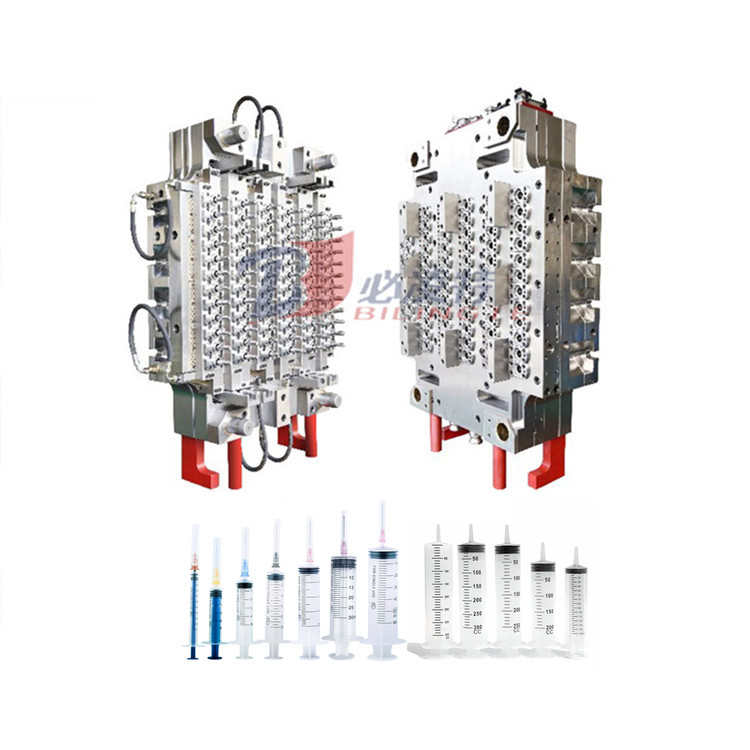

Blood Collection Tube Mold Main feature

1.Blood collection tube mold cavity from 1 up to 144.

2.Electric control system with simulating stretch testing improve yield rate.

3.Adopt world advanced dipole taper localization technique, each cavity self-clamp independently, ensure mould concentricity.

4.The material of mould die core and die cavity are made of Sweden special mould steel.

5.International standard screw neck, imported nitrided steel with high hardness is of long usage.

6.Advanced hot runner design and even heating temperature make sure the high quality of plastic products.

7.At least 3 million guarantee.

Precision Tooling Equipment

All of machine parts are manufactured by CNC equipments.

Our workers are fully qualified and skilled at using modern production techniques. Computerized CNC (Computer Numeric Coordinates) Systems (CAD/CAM) produce new machines with money-saving speed and accuracy. We employ a wide range of manual, automatic and computerized equipment in making machines.

Current Location:

Current Location: